QuickCut

NC-Programmiersystem für die Aufteilung von PKD-Ronden auf Drahterosionsmaschinen.

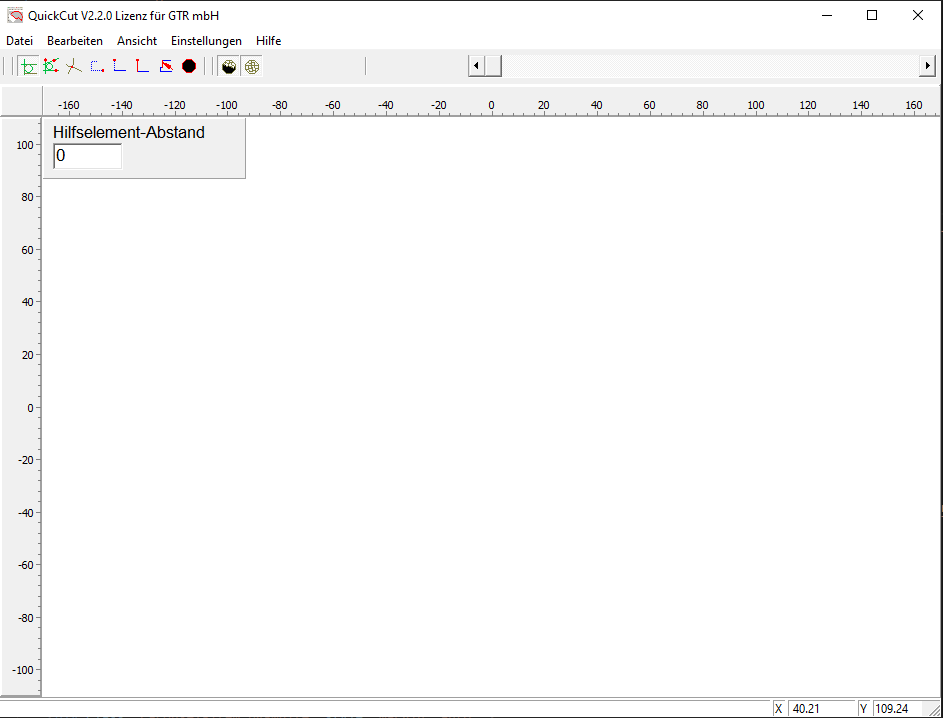

Ausgefeilte Bedienoberfläche

Alle wichtigen Funktionen sind über Menü oder Werkzeugleiste und auch über Funktionstasten aufrufbar. Damit ist das Programm sowohl für Gelegenheitsanwender als auch für geübte Anwender optimal bedienbar.

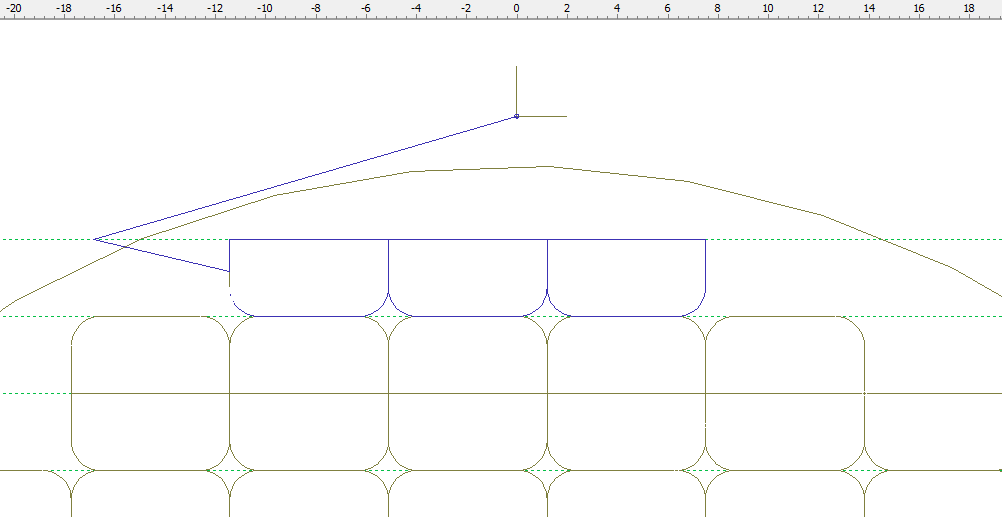

Erzeugung von Hilfsgeometrien

Zum Optimieren der Verfahrwege können Hilfsgeometrien erzeug werden.

Programmieren der Anfahr- und Verfahrwege

Mit wenigen klicks können die Anfahrwege sowie die Verwahrwege in der Ronde programmiert werden.

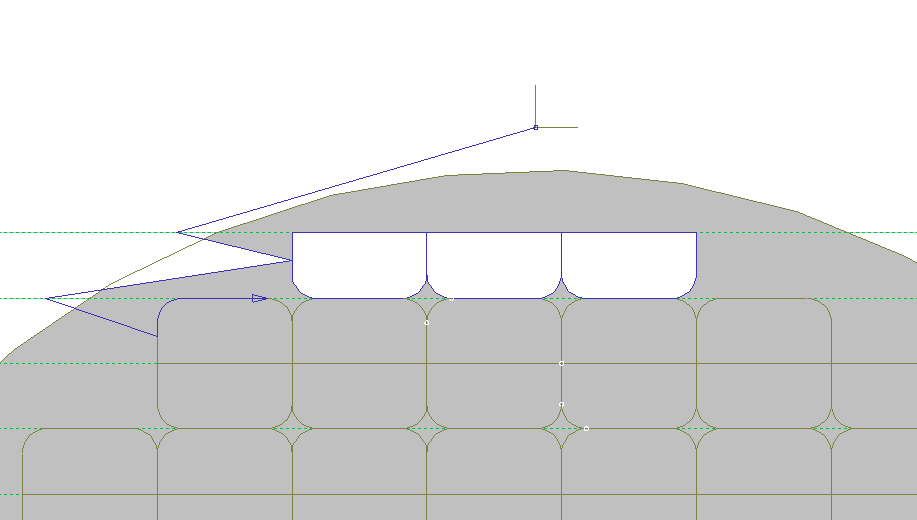

Visualisierung des herausgefallenen Teils

Wenn eine Schneidkontur mit den Verfahrwegen umschlossen wird und dies herausfällt, wird ds Segment weiß angezeigt.

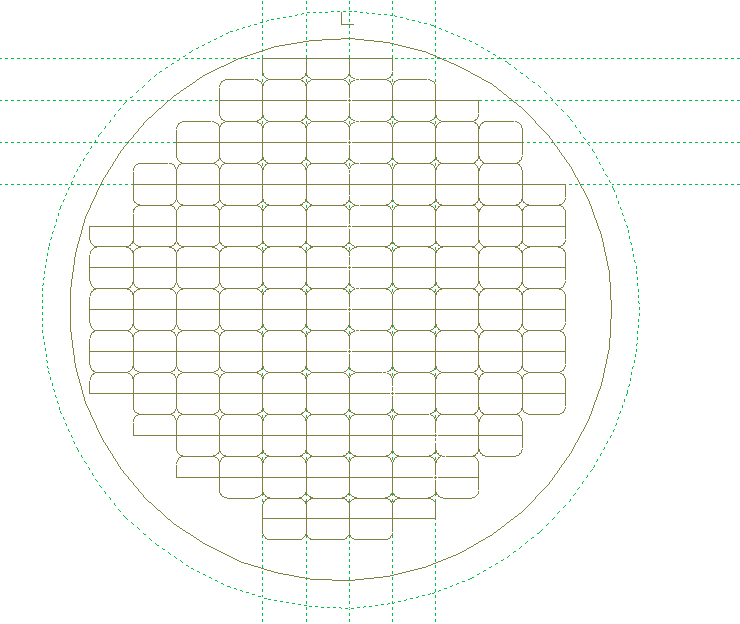

Das Erstellen der NC-Programme für die Aufteilung von PKD-Ronden, entsprechend den oben gezeigten Beispielen, ist eine zeitaufwendige Arbeit. Wenn sich hierbei Fehler einschleichen führt dies häufig dazu, dass teures PKD-Material unbrauchbar wird.

Das Programm QuickCUT von GTR wurde speziell zur Lösung dieser Aufgabenstellung entwickelt und unterstützt die Bearbeitung mit optimierten Funktionen. Als Ausgangsbasis benötigt das Programm DXF-Dateien, in welchen der Rondenumriss und die Umrisskanten der auszuschneidenden Teile enthalten sind. Die Teile müssen so gezeichnet sein, dass die Umrisskanten der Mittelpunktsbahn des Erodierdrahtes entsprechen. Die DXF-Daten können von einem beliebigen CAD-System oder von einem automatischen Schachtelprogramm kommen. QuickCut unterstützt die Erstellung des NC-Programms mit folgenden Leistungsmerkmalen:

- Ausgefeilte Bedieneroberfläche entsprechend Windows-Standard. Alle wichtigen Funktionen sind über Menü oder Werkzeugleiste und auch über Funktionstasten aufrufbar. Damit ist das Programm sowohl für Gelegenheitsanwender als auch für geübte Anwender optimal bedienbar.

- Jederzeit (auch während der Bearbeitung anderer Funktionen) per Funktionstasten aufrufbare Zoomfunktion zur Einstellung des gewünschten Zeichenfeldausschnitts.

- Erstellen von Hilfsgeometrie für die Festlegung von Startpunkt und Anfahrwegen sowie Anzeige der festgelegten Schnittwege mit Richtungspfeil am jeweiligen Schnittwegende.

- Auftrennen von Elementen der DXF-Geometrie an Schnittpunkten zur Vereinfachung der Konturverfolgung.

- Beliebiges Festlegen der Schnittwege entlang der DXF-Kontur oder von Punkt zu Punkt, unterstützt durch leistungsfähige Fangfunktionen (Endpunkte, Schnittpunkte, Mittelpunkte, Lotpunkte).

- Automatische Verfolgung von zusammenhängenden Konturzügen (gesamte Umrisskante mit einem Mausklick).

- Farbliche Abgrenzung der beim jeweiligen Stand der Schnittwegfestlegung abgetrennten Rondenteile

- Simulation des Schnittfortschritts (mit Funktionstasten Einzelschritte rückwärts und vorwärts, zum Beginn und zum Ende des Schnitts sowie mit Schieberegler schnell an eine beliebige Position des Schnittverlaufs)

- Korrekturmöglichkeiten für die festgelegten Schnittwege (ausschneiden, kopieren, löschen, einfügen)

- Eingabe der Technologiedaten (Register)

- Speichern und wiedereinlesen der Arbeitsdaten

- Erstellen einer steuerungsunabhängigen CL-Data-Datei

- Erzeugung des NC-Programms für den jeweiligen Steuerungstyp (Postprozessoren für AGIE CNC 100 und CNC 123 sowie für Fanuc-Erodiermaschinen verfügbar)