ProfDia® / ProfDiaF® Laser

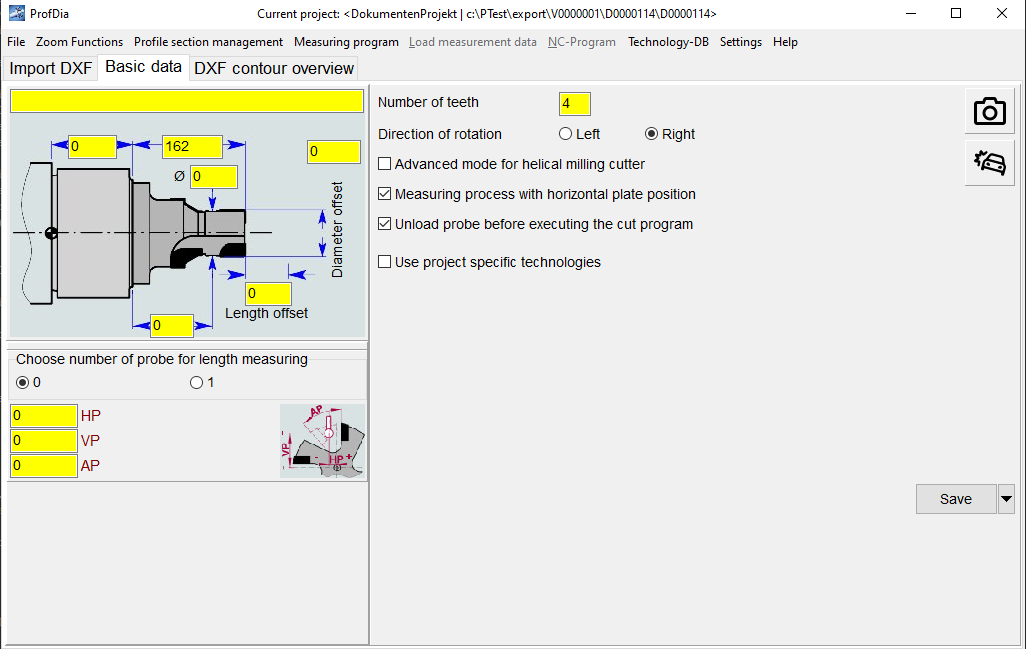

Programmierung der Schneide

Übersichtliche Eingabemaske der Schneidgeometrien.

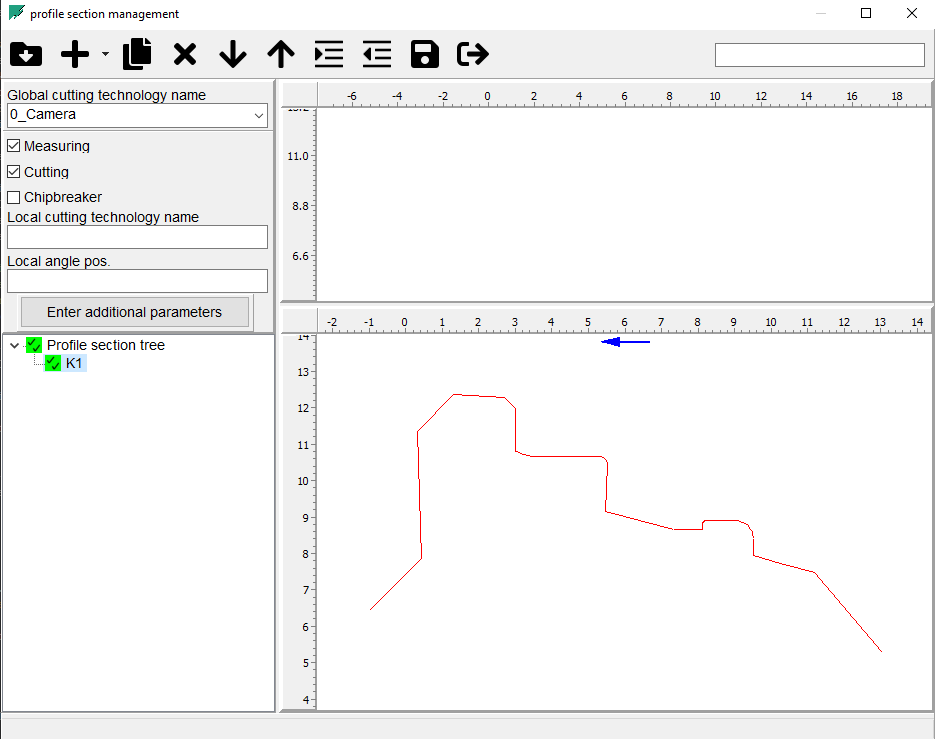

Selektieren der Schneidgeometrie

Einfaches einfangen der Schneidgeometrie aus der importierten DXF-Datei

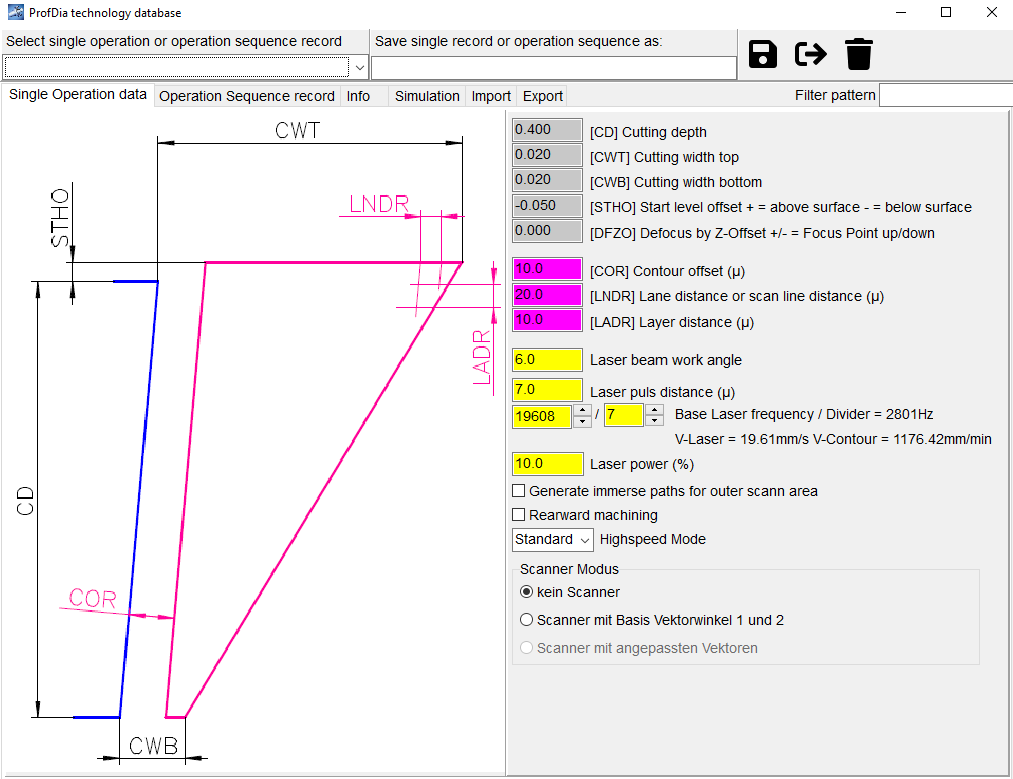

Definieren der passenden Schneidtechnologien

Einfaches und schnelles anpassen der Schneidtechnologien.

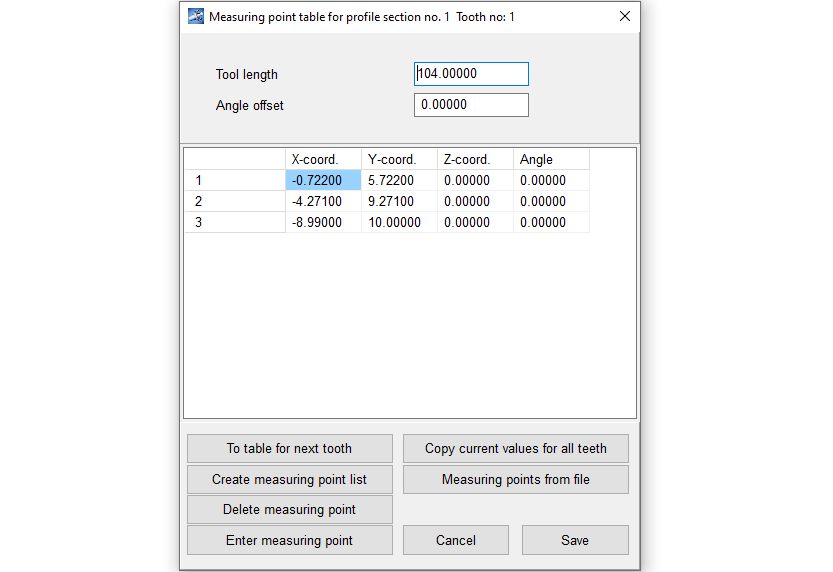

Automatisiertes Einlesen der Messdaten aus der Maschine

Die Schneide wird vor dem Schneiden eingemessem um das Schneidprogramm an die realität anzupassen.

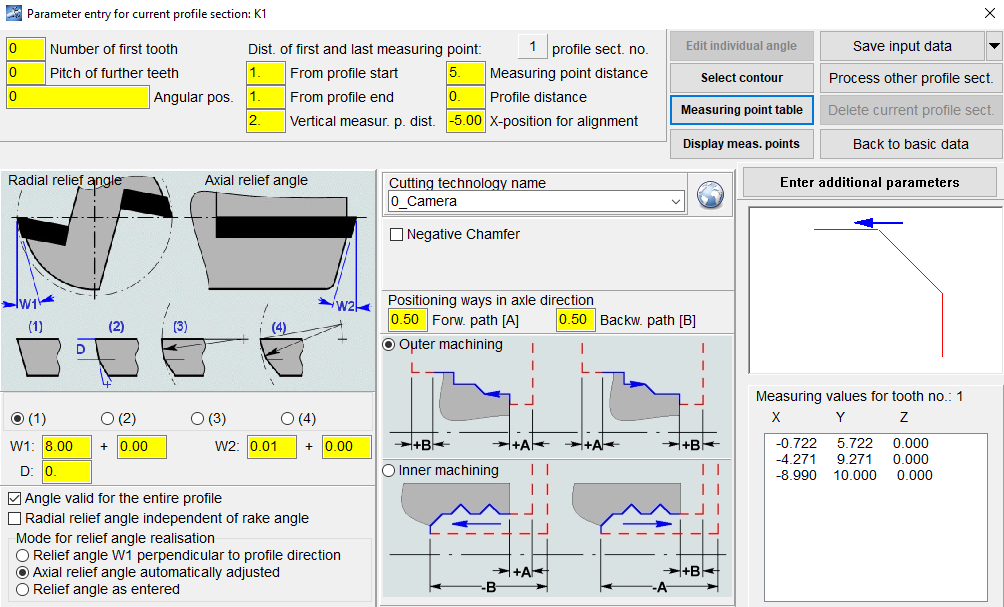

Teilkontur Parametereingabe

Übersichtliche Eingabe der Teilkontureigenschaften.

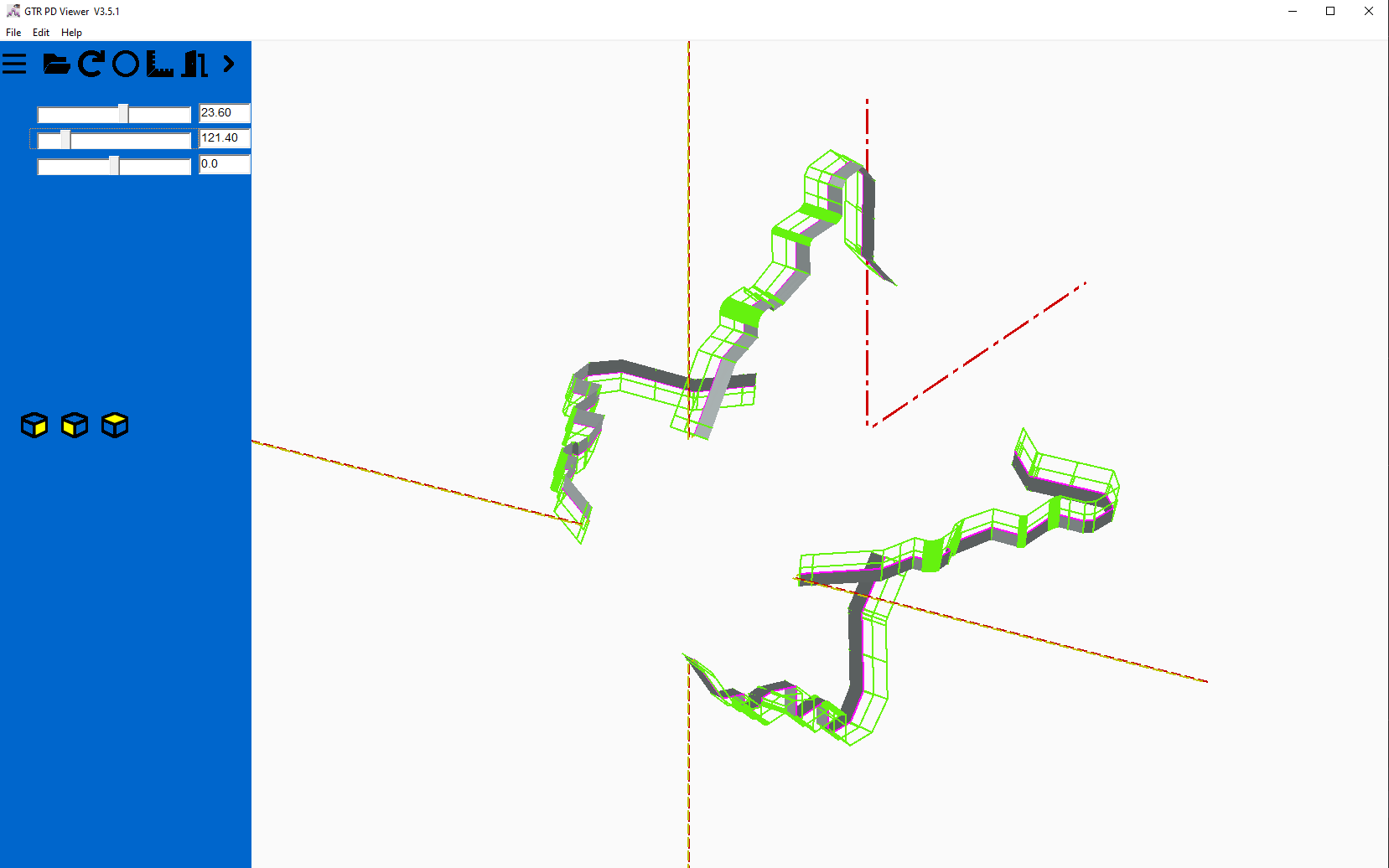

3D-Simulation

Überprüfung der programmierten Schneide mittels praktischer 3D-Simulation.

Das ProfDia-Softwaresystem unterstützt die Erstellung von NC-Programmen zur hochgenauen Profilierung von Diamantwerkzeugen (PKD) auf Lasermaschinen.

Die GTR Software ProfDia® und ProfDiaF® ist in der Lage für entsprechend ausgerüstete Maschinen das erforderliche Messprogramm zu erstellen, die ermittelten Messdaten einzulesen und mit diesen Messdaten ein exakt angepasstes Schneidprogramm zu generieren. ProfDia® und ProfDiaF® unterscheiden sich im wesentlichen darin, dass ProfDia® für rotierende Werkzeuge und ProfDiaF ® für feststehende Werkzeuge optimiert ist.

Folgende Merkmale der ProfDia® Programmieroberfläche erlauben eine einfache und intuitive Programmerstellung ohne spezielle Programmierkenntnisse:

- Konturübernahme im DXF-Format aus einem beliebigen CAD-System

- Parametereingabe in spezialisierte, selbsterklärende Eingabemasken

- Verwaltung beliebig vieler Technologiedatensätze für verschiedene Bearbeitungen und Werkstoffe

- Festlegen der Messpunkte für die Vermessung der Werkzeuge

- Generierung des Messprogramms für die automatische Vermessung der Werkzeuge

- Einlesen der Messdaten von der Lasermaschine

- Übertragung des Messprogramms an die Lasermaschine

- Generierung der NC-Programme für die Lasermaschine

- Übertragen der NC-Programme an die Lasermaschine

- Gesamter Produktionszyklus voll automatisierbar

- Gesamtkontur in eine beliebige Anzahl von Teilkonturen mit individuellen Parametern aufteilbar

- Festlegen der Bearbeitungsparameter (Freiwinkel, Anzahl Schnitte, An- und Abfahrwege usw.)

- Graphische Simulation von Mess- und Schneidprogramm unterstützt die Erstellung fehlerfreier Programme

- Einfache Handhabung durch optimierte Funktionen für den Programm- und Messdatentransfer zwischen Programmierrechner und Maschine

- Gesamter Produktionszyklus voll automatisierbar

- Verwaltung der mit dem ProfDia-Hauptprogramm erfassten Daten mit verschiedenen Ordnungsmerkmalen. Suchfunktionen nach beliebigen Merkmalen schaffen einen schnellen Überblick und Zugriff auf die erfassten Daten.