Ihr Partner für CAD/CAM

Auf einen Blick

| Firmenname | Gesellschaft für technische Rechneranwendungen mbH (Society for technical software solutions) |

|---|---|

| Firmensitz | Aalen, Germany |

| Anschrift | GTR mbh, Felix-Wankel Straße 10, 73431 Aalen |

| Geschäftsführer | Bastian Teufel |

Firmenhistorie

-

Gründung durch Rainer Karle

Die GTR mbH wurde von Dipl.Ing.(FH) Rainer Karle zunächst als iTRA (Ingenieurbüro für technische Rechneranwendung) gegründet. Herr Karle war nach dem Maschinenbau-Studium zunächst bei einem großen Holzbearbeitungswerkzeughersteller beschäftigt. Dort wurde er mit der Einführung von Varianten-Konstruktionsprogrammen für Werkzeugkomponenten vertraut. Die Anwendung der Programme rationalisierten den Konstruktions- und Fertigungsprozess der Komponenten erheblich. Daraus entstand das Geschäftsmodel für das Ingenieurbüro, nämlich für Kunden mit hochvariablen Werkstücken die Konstruktionslogik in Programmen abzubilden und daraus alle erforderlichen Zeichnungen und Fertigungsdaten abzuleiten. Zu diesem Zeitpunkt gab es leider noch keine PCs mit einheitlichem Betriebssystem. Jeder Computerhersteller hatte sein eigenes Betriebssystem. Dadurch konnte das Geschäftsmodell nur in geringem Umfang realisiert werden.

-

Einstieg in die NC Technik

Erste PCs mit dem Betriebssystem CP/M kamen auf den Markt. Von der gewerblichen Ausbildung wurden kostengünstige NC-Programmiersysteme für die Ausbildung angefragt. In Zusammenarbeit mit einem Hardwarelieferanten wurde für Triumph Adler Alphatronic PCs das CAM System „NC2000“ mit interaktiver Grafik entwickelt und an einigen Ausbildungsstätten installiert. Über eine serielle Schnittstelle konnten auch CNC-Maschinen an den PC angebunden werden. Der Einstieg in die NC-Technik war vollzogen.

-

Einstieg Geschäftsfeld Holzbearbeitung

Ein Kunde aus der Werkzeugbranche entschied sich auch CNC-Maschinen für die Holzbearbeitung herzustellen. Die bereits vorhandenen CAM-Systeme waren für die Metallbearbeitung geeignet, enthielten aber keine holzspezifischen Funktionen und vor allem keine einfach handzuhabende Variantentechnik. Unter MS-DOS wurde das CAM System „WoodCAM“ entwickelt welches genau für diesen Einsatz konzipiert war. Es enthielt eine ausgefeilte Variantentechnik mit Elementreferenzierungen, Variablen, Sprüngen, Schleifen, Makrotechniken und einer einfachen Werkzeugverwaltung. Bei einigen Kunden wird das System heute noch z.B. zur Haustürproduktion eingesetzt. Es wurde später auch auf Windows portiert.

-

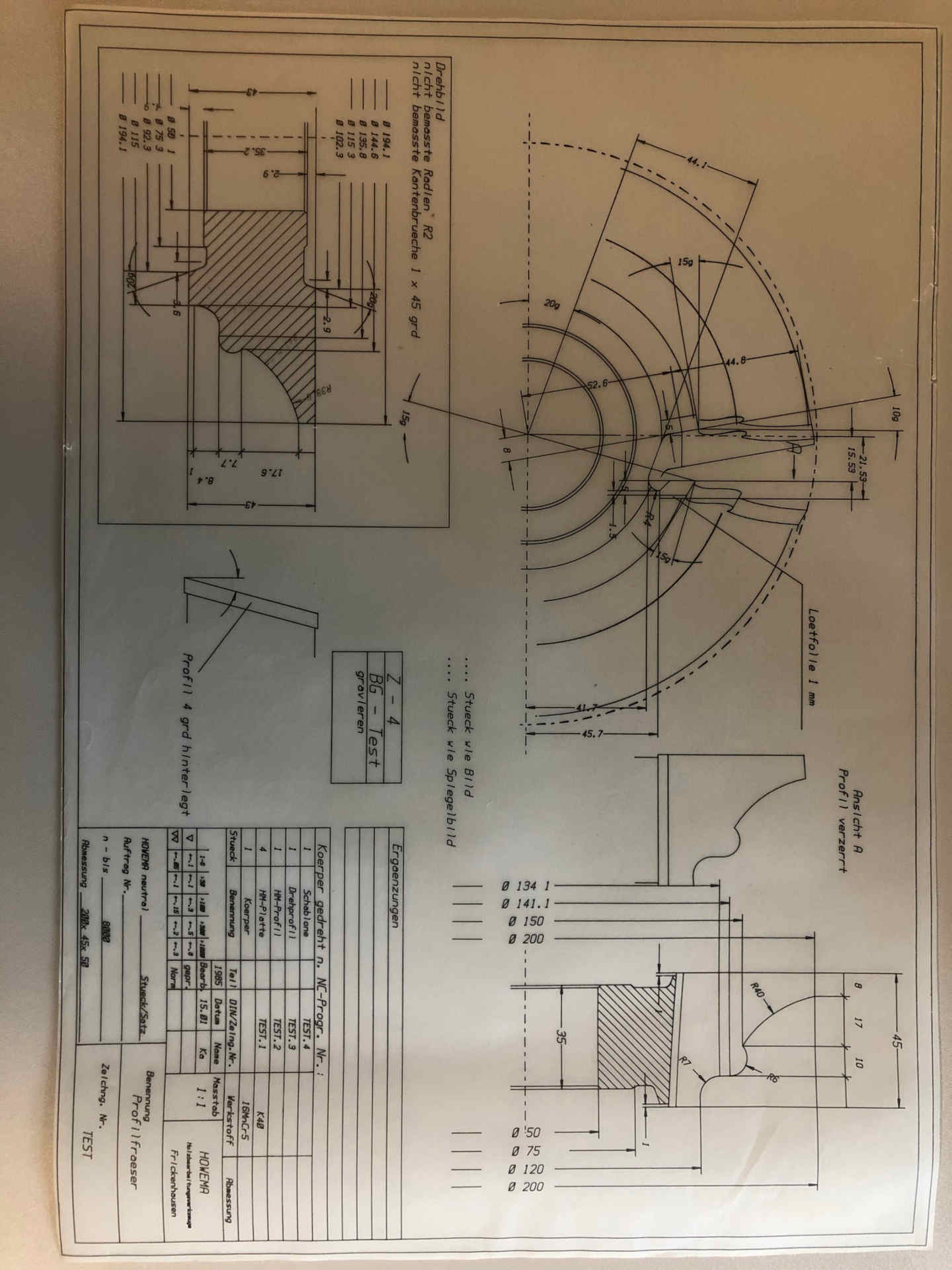

Einstieg Geschäftsfeld Werkzeugtechnik

Zu Beginn der 1990 Jahre kamen immer mehr PKD-Werkzeuge zunächst in der Holzbearbeitung zum Einsatz. Die Schneiden konnten geschliffen und mit funkenerosiven Verfahren bearbeitet werden. In Zusammenarbeit mit dem Drahterosionsmaschinen-Hersteller AGIE wurde die Software „AGIETool“ entwickelt. Mit deren Hilfe konnten Schneidenprofile beschrieben, die Verzerrung berechnet und das Erosionsprogramm ausgegeben werden.

-

Firmenumzug

Umzug in ein eigenes Firmengebäude. Seit dato ist dies der Sitz von GTR.

-

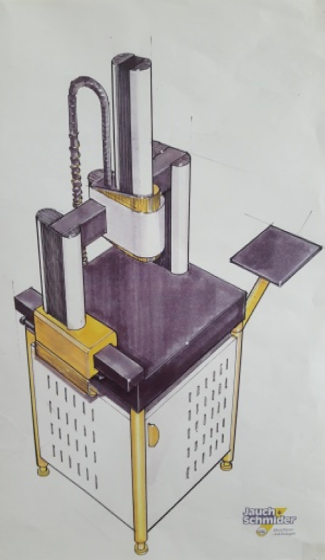

Entwicklung Messmaschine für Drahterosionsmaschinen

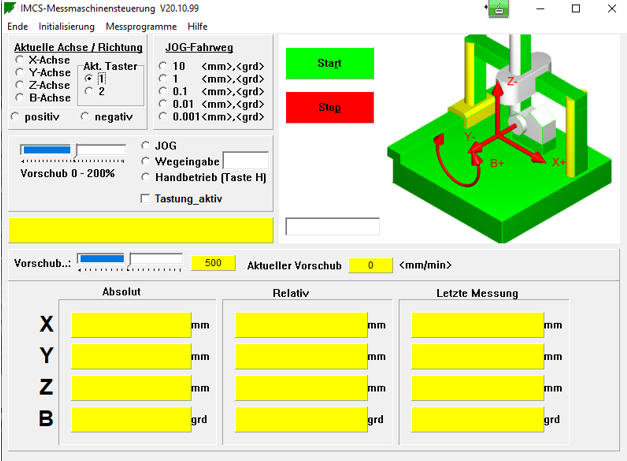

Als großer Nachteil des Drahterosionsprogramms erwies sich, dass die genaue Schneidenlage nicht gemessen werden konnte. Das Programmiersystem für die PKD-Bearbeitung mit Drahterosion wurde neu aufgesetzt. In Zusammenarbeit mit einem Industriedesigner und der Firma Jauch&Schmider wurde diese Messmaschine entwickelt:

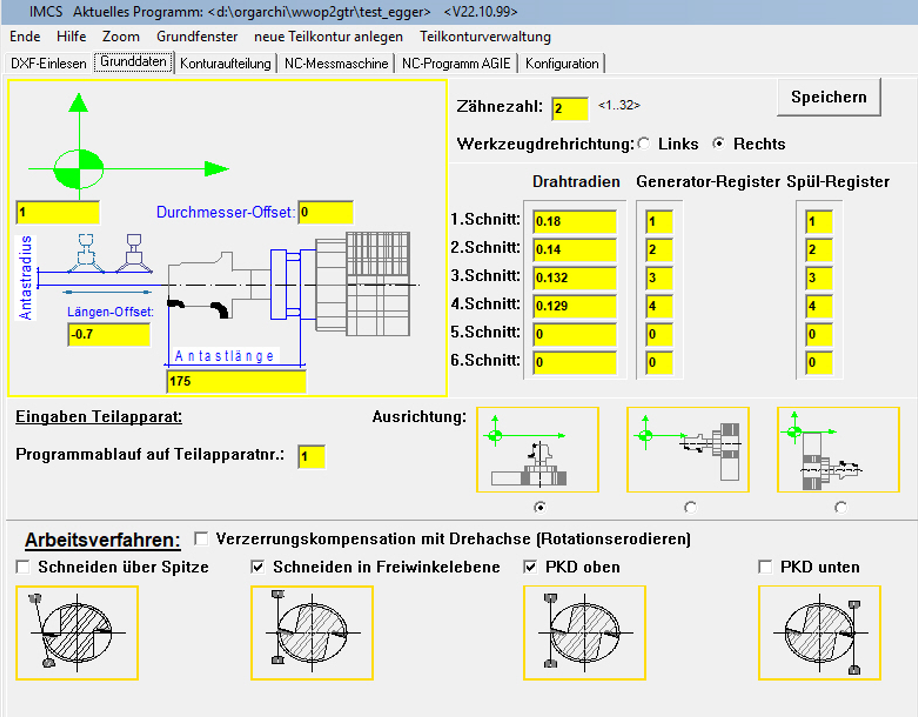

Mit dem System konnten die Schneidenlagen der Werkzeuge auf der Messmaschine bestimmt, die Daten in das Programmiersystem IMCS_DIA eingelesen und zur Berechnung verwendet werden:

-

Entwicklung I-CAD Vellum 4.0

In Zusammenarbeit mit der Firma Vellum Software GmbH und dem Vertriebspartner I-CAD wurde in das CAD Programm I-CAD Vellum 4.0 eine CAM Oberfläche programmiert. Diese Funktion ermöglicht dem Anwender aus der Zeichnung die CNC- oder WOP-Programme zu generieren. Die Anwendung des CAD-Programms als auch des CAM-Modules ist sehr einfach. Deshalb wurde das System auch an einer Vielzahl von Schulen installiert und ist dort auch noch heute im Einsatz. Meilensteine der Entwicklungen in der Holzbearbeitung:

• Berechnung der optimalen, kollisionsfreien Saugerpositionen zum schnellen Rüsten der CNC-Maschinen

• Kollisionsberechnung des Leimaggregates mit der zu bearbeitenden Kontur und automatische Nachführung. Technologiedatenbank für Verleimparameter

• Automatische Mehrschichtbeleimung

-

Erste Veröffenttlichung von ProfDia und ProfDiaF für Drahterosionsmaschinen

Das Programmiersystem wurde neu aufgesetzt und um die Funktion erweitert mit deren Hilfe und eines an der Erosionsmaschine angebrachten Messtasters die Schneidenlage bestimmt und an das Programmiersystem zurückgegeben werden konnte. Das CAM System ProfDIA für rotierende Werkzeuge und ProfDIAF für Drehstähle wurde ab diesem Zeitpunkt auf dem Markt eingesetzt und wird bis heute ständig erweitert und optimiert.

-

Implementierung 3D Programm in Solidworks

Nachdem die Erweiterung von dem CAD-Programm Vellum bzw. DraftBoard zu einem CAD/CAM System gut funktionierte und von den Kunden angenommen wurde, sollte so ein Verfahren in das 3D Programm SolidWorks implementiert werden. Zu diesem Zeitpunkt begann die Firma PASCAM mit der Entwicklung eines CAM-Moduls für die Holzbearbeitung mit SWX. Es wurde eine Zusammenarbeit vereinbart mit der Aufgabenteilung, dass GTR die Entwicklung aller Module übernimmt welche zur Ansteuerung der CNC-Maschinen erforderlich sind. Dazu gehörte: die Werkzeugdatenbank, die 3D Simulation, die Postprozessoren bzw. WOP Generatoren für die Holzbearbeitungsmaschinen. Das System ist automatisierbar und dadurch konnten Kunden gewonnen werden, die in das System den vollständigen Konstruktions- und Produktionsprozess einbinden konnten.

-

Erste Version ProfDia und ProfDiaF für Lasermaschinen von Sauer Lasertec GmbH (Heute DMG Mori Lasertec)

In Zusammenarbeit mit einem großen Lasermaschinenhersteller wurden ProfDIA und ProfDIAF an dessen Maschinen angepasst. Es wurde erheblicher Entwicklungsaufwand erforderlich bei dem einige neue Verfahren entwickelt werden mussten um die Werkzeugschneiden schnell und genau zu profilieren. Das Programmiersystem arbeitet erfolgreich und zuverlässig. Der Maschinenhersteller ist seit mehreren Jahren Marktführer in dem Bereich Laser-Werkzeugprofilierung.

-

Anpassung von ProfDia für Vollmer Lasermaschine

Im Jahr 2016 begann GTR Exprog an die Vollmer Lasermaschine anzupassen.

-

Übernahme durch Bastian Teufel

Im Jahr 2018 wurde die Firma von Dipl.Ing.(FH) Bastian Teufel übernommen. Rainer Karle arbeitet als freier Mitarbeiter für GTR und steht der Firma mit seinem Expertenwissen zur Verfügung.

-

Neuer Mitarbeiter Manuel Ziesel

Seit Oktober 2020 Arbeitet Manuel Ziesel für uns. Er ist hauptsächlich damit beschäftigt die ProfDia/F Produkte weiter zu entwickeln.

-

Neue Partnerschaft mit OPMTE

Seit 2022 hat GTR die ProfDia/F Produkte an die Lasermaschinen von OPMTE angepasst und hat somit einen Partner im asiatischen Bereich.

-

Neue Partnerschaft mit Walter/EWAG

Im Jahr 2022 begann GTR die Entwicklung und Anpassung von ProfDia an die Lasermaschinen von Walter/EWAG.

-

Neue Mitarbeiterin Martina Schlude

Seit Juni 2023 Arbeitet Martina Schlude für uns. Sie löste unsere langjährige Mitarbeiterin Andrea Heil ab, welche in den Ruhestand ging, und ist seitdem die neue Assistentin der Geschäftsleitung.

-

40 Jähriges Firmjubiläum

Im Sommer 2024 Feierte das GTR mbH Team mit allen Mitarbeitern, Angehörigen und ehemaligen Mitarbeitern der Firma bei einem Grillfest das Firmenjubiläum.

-

Neuer Mitarbeiter Paolo Mori

Seit November 2024 Arbeitet Paolo Mori für uns. Er ist hauptsächlich damit beschäftigt die ProfDia/F Produkte weiter zu entwickeln.